Hello

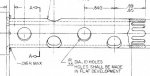

It seems we cannot bend and roll two different sections at the same time. How about if we make one section in solid and the bottom section in sheetmetal? Surprisingly, PTC hasnt been more flexible on this topic. Also the holes were drilled at the flat sheet, this is also a problem.. Another question is the punches. How do meet the punch dimensions in the tube2. picture? There are 5 knobs equally spaced, that is 72 deg apart.

joe

It seems we cannot bend and roll two different sections at the same time. How about if we make one section in solid and the bottom section in sheetmetal? Surprisingly, PTC hasnt been more flexible on this topic. Also the holes were drilled at the flat sheet, this is also a problem.. Another question is the punches. How do meet the punch dimensions in the tube2. picture? There are 5 knobs equally spaced, that is 72 deg apart.

joe