Hello all,

I am having a hard time trying to figure out how to make a particular sheetmetal part, particularly how to punch the way I want it to, unless there's a better way to do it altogether...

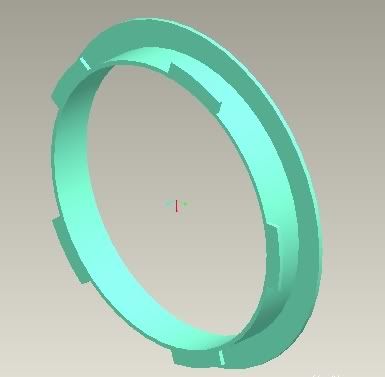

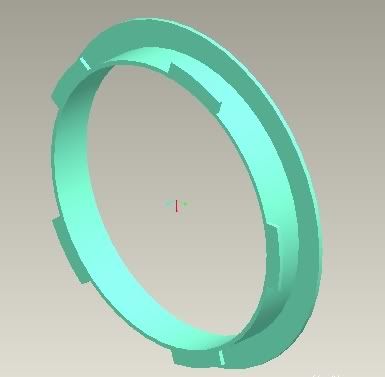

The image aboveis a rough representation of what I want the finished part to look like, modeled as a standard part (obviously bend radii and reliefs are not shown).

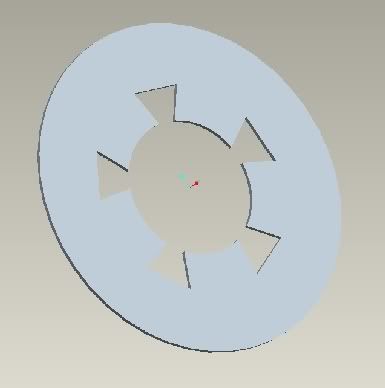

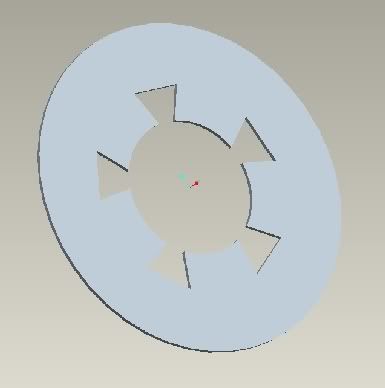

How I've been trying to do this is to start with a flat "donut" with the 5 tabs included:

At this point I have created a punch with the idea that I'll end up with a flanged cylindrical part, and from there I will bend the tabs out to end up with something like the image at the top.

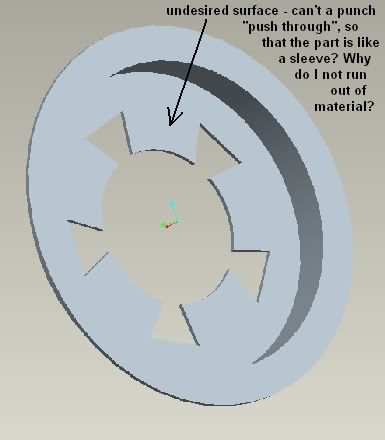

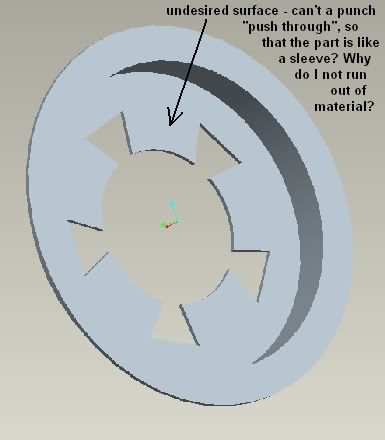

The problem I'm having is that no matter how deep I make my punch, Pro/E wants to leave a bottom surface, so that I end up with a flanged"cup", instead of a flanged "sleeve":

If I make the punch deeper, the cup justends updeeper.

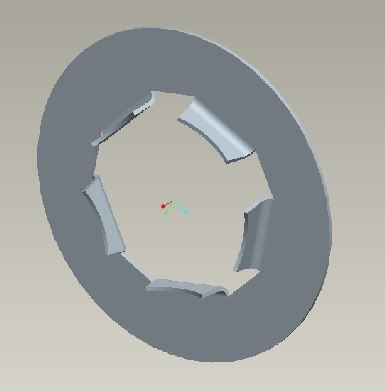

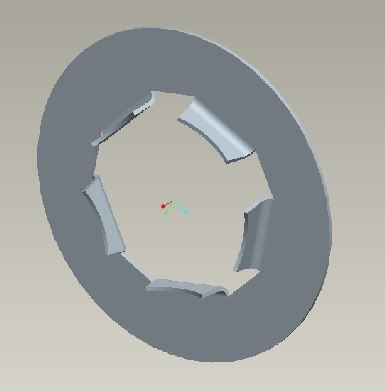

If I bend the tabs out first like in the image below, I get a failure when I attempt the punch:

If I leave the tabs off altogether and attempt to form a flanged cylinder, I still end up with the "cup with a hole in the bottom".

Does anyone have any ideas as to how I can accomplish what I'm going for? It may turn out that I'm going about this the wrong way from the get-go, but any tips or ideas would be greatly appreciated.

I am having a hard time trying to figure out how to make a particular sheetmetal part, particularly how to punch the way I want it to, unless there's a better way to do it altogether...

The image aboveis a rough representation of what I want the finished part to look like, modeled as a standard part (obviously bend radii and reliefs are not shown).

How I've been trying to do this is to start with a flat "donut" with the 5 tabs included:

At this point I have created a punch with the idea that I'll end up with a flanged cylindrical part, and from there I will bend the tabs out to end up with something like the image at the top.

The problem I'm having is that no matter how deep I make my punch, Pro/E wants to leave a bottom surface, so that I end up with a flanged"cup", instead of a flanged "sleeve":

If I make the punch deeper, the cup justends updeeper.

If I bend the tabs out first like in the image below, I get a failure when I attempt the punch:

If I leave the tabs off altogether and attempt to form a flanged cylinder, I still end up with the "cup with a hole in the bottom".

Does anyone have any ideas as to how I can accomplish what I'm going for? It may turn out that I'm going about this the wrong way from the get-go, but any tips or ideas would be greatly appreciated.