TWINTURBOTOM

New member

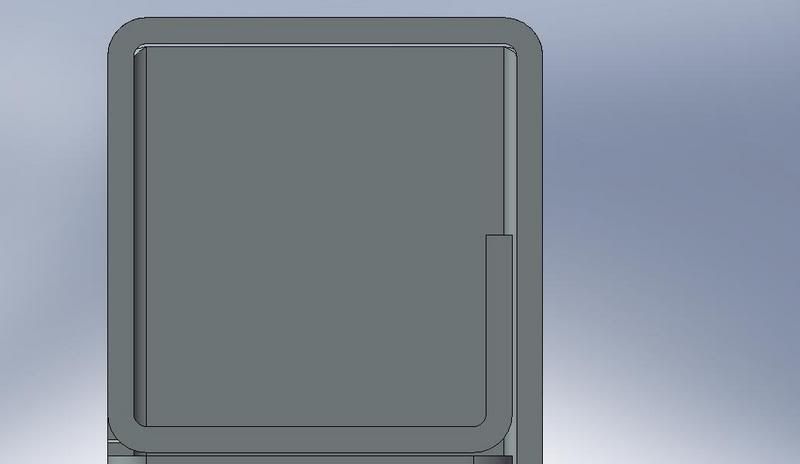

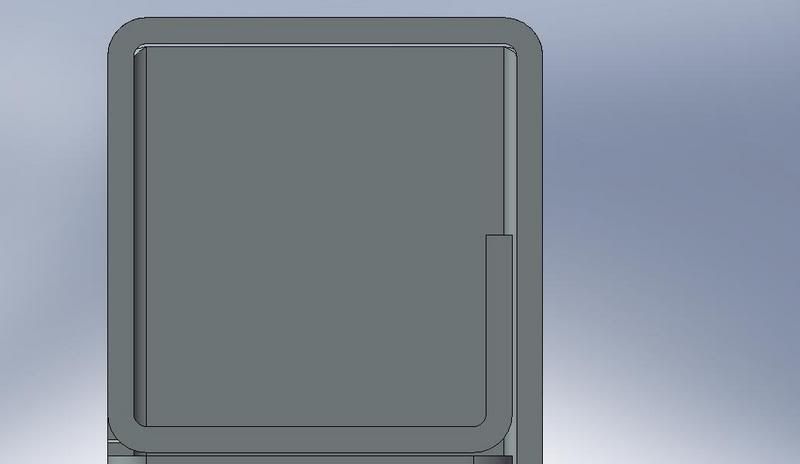

attached is a xsec of the situation..... it's a base wall (farthest right in view) with 4 flanges....it is set up in a "loop" so that the last flange will have inserts allowing one to use screws from the base wall into the last flange...you can also see the bends from a wall behind this situation...pay no attention to that...it does not interfere, from that view it looks like it does......

this part is just me playing with sheetmetal for the first time (had solidworks for about 1 week...) the last flange will not rebuild withoutan errorunless their is a gap between the base wall and the flange...i have .01" clearance in that pic...when i move the gap to zero it gives errors??? why??? I can't have a flush fit here??? is this in issue with my tolerance setup??? I was goin go to the sketch and try to make the line in the sketch coincident to the base wall.... not sure whats up...any input? thanks....

this part is just me playing with sheetmetal for the first time (had solidworks for about 1 week...) the last flange will not rebuild withoutan errorunless their is a gap between the base wall and the flange...i have .01" clearance in that pic...when i move the gap to zero it gives errors??? why??? I can't have a flush fit here??? is this in issue with my tolerance setup??? I was goin go to the sketch and try to make the line in the sketch coincident to the base wall.... not sure whats up...any input? thanks....