Hi,

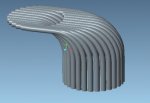

I have to create an assembly (Creo 2.0) for a heat exchanger, which is basically a big, bent pipe (section diameter ~2m) which "coat" itself consists of a great number of small pipes (section diameter ~50mm).

The number of small pipes, their diameter and more are controlled by parameters in the top assembly. Now, in a sub-assembly I'm trying to create said coat of the bigger pipe. My first thought was to create a generic small pipe (as a part), then assemble it and create some sort of pattern that creates all missing pipes following the outer perimeter of the big pipe.

Unfortunately, this would also require that each pattern element automatically changes its dimensions, since a pipe at the upper/outer part of the big pipe would differ from a pipe at the lower/inner part in terms of lenght and diameter.

I've played around a lot, but I can't get it to work properly. I know, for example, that it is possible to control pattern increments via relations, though I've got no idea how this could be useful in my case.

Any help or suggestions for a different approach would be appreciated!

I have to create an assembly (Creo 2.0) for a heat exchanger, which is basically a big, bent pipe (section diameter ~2m) which "coat" itself consists of a great number of small pipes (section diameter ~50mm).

The number of small pipes, their diameter and more are controlled by parameters in the top assembly. Now, in a sub-assembly I'm trying to create said coat of the bigger pipe. My first thought was to create a generic small pipe (as a part), then assemble it and create some sort of pattern that creates all missing pipes following the outer perimeter of the big pipe.

Unfortunately, this would also require that each pattern element automatically changes its dimensions, since a pipe at the upper/outer part of the big pipe would differ from a pipe at the lower/inner part in terms of lenght and diameter.

I've played around a lot, but I can't get it to work properly. I know, for example, that it is possible to control pattern increments via relations, though I've got no idea how this could be useful in my case.

Any help or suggestions for a different approach would be appreciated!